Scientists at Stanford University have identified a straightforward solution to one of the biggest obstacles holding back next-generation batteries. By applying an extremely thin layer of silver to the surface of a solid-state battery's ceramic core, researchers have made the material nearly five times more resistant to cracking.

The findings, published in Nature Materials on January 16, address a fundamental problem that has frustrated battery researchers for decades. Solid-state batteries promise major advantages over today's lithium-ion batteries—they could store significantly more energy, charge much faster, and operate more safely. Yet they remain largely confined to laboratories because the ceramic materials used inside them develop microscopic cracks that grow over time and eventually cause complete failure.

Background

Solid-state batteries work differently from the lithium-ion batteries that power phones, laptops, and electric vehicles today. Instead of using a liquid electrolyte—the chemical substance that allows ions to flow between the battery's positive and negative terminals—solid-state batteries use a solid ceramic material. This solid design offers real benefits. It eliminates the flammable liquid inside conventional batteries, making them safer. It also allows for higher energy density, meaning more power in the same space, and faster charging times.

However, manufacturing solid electrolytes from crystalline materials creates a persistent problem. The materials are brittle and prone to developing tiny cracks during production and use. These small fractures become dangerous during fast charging, when the battery pushes large amounts of electrical current through the material. The stress causes small cracks to expand into larger channels that permanently damage the battery's ability to function. Lithium, the chemical that powers the battery, can also seep into these cracks and form harmful structures that degrade performance further.

Previous research had shown exactly how these cracks form and spread, but finding a practical way to prevent them has proven difficult. Making batteries completely free of defects during manufacturing is nearly impossible and would be prohibitively expensive. This is where the Stanford team's approach differs from earlier attempts.

Key Details

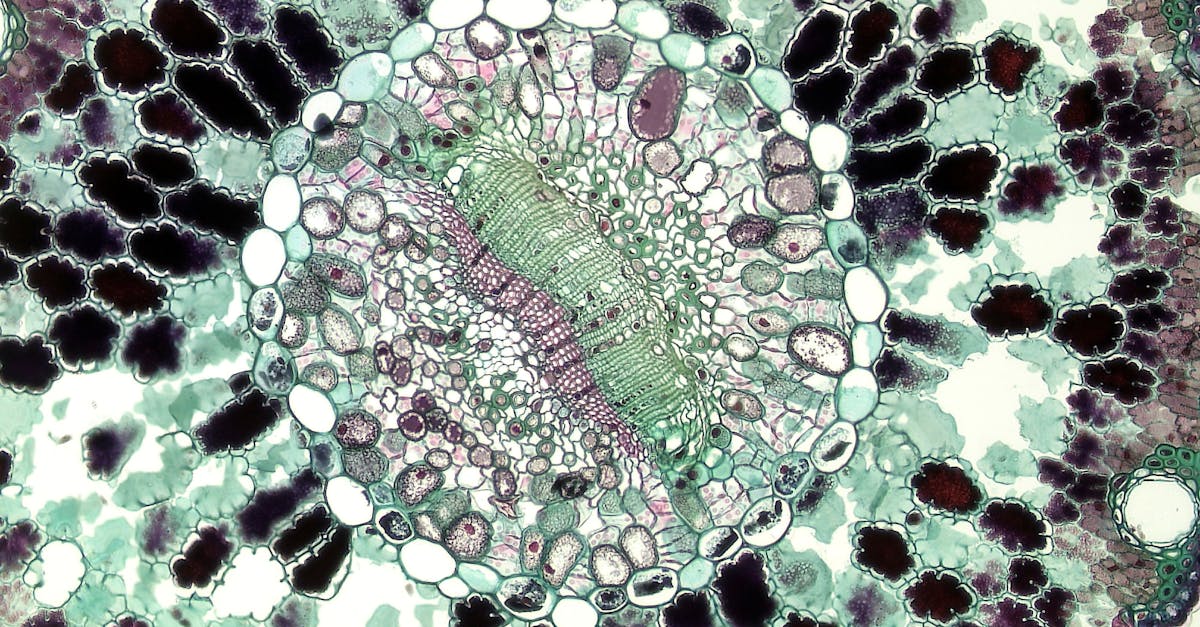

The Stanford researchers focused on a ceramic material called LLZO, which stands for lithium, lanthanum, zirconium, and oxygen. They applied a silver layer just three nanometers thick—roughly the width of a few atoms—to the surface of LLZO samples and then heated the material to 300 degrees Celsius (572 degrees Fahrenheit).

During heating, something unexpected happened. The silver atoms moved into the surface of the electrolyte, replacing the smaller lithium atoms within the material's porous crystal structure. Crucially, the silver remained in an ionic form—meaning it had lost an electron and carried a positive charge. This positively charged silver, rather than solid metallic silver, proved to be the key to strengthening the ceramic.

"We decided a protective surface may be more realistic, and just a little bit of silver seems to do a pretty good job." – Gu, Stanford researcher

The silver ions created a protective barrier that extended roughly 20 to 50 nanometers below the surface. This barrier made the material significantly harder and more resistant to fracturing under pressure. When researchers tested the treated material using a specialized probe inside a scanning electron microscope, they found it required almost five times more force to crack compared to untreated samples.

The silver ions also blocked lithium from entering and expanding within existing surface flaws. This protection proved especially important during fast charging, when stress on the material is greatest.

How This Differs From Earlier Work

Other research teams had previously examined metallic silver coatings on the same LLZO material, but those efforts focused on solid silver rather than dissolved silver ions. The Stanford team's approach of using positively charged silver ions produced dramatically better results. Researchers also tested copper, which worked to some degree, but silver remained the most effective option.

What This Means

The Stanford team is now moving beyond small laboratory samples to test the silver treatment on full battery cells. The next critical question is whether the protective coating can survive thousands of charging cycles—the number needed for an electric vehicle battery to last a decade of normal use.

If the technology can be scaled up successfully, it could have major implications for battery development. Solid-state batteries could finally move from research labs into commercial products, enabling electric vehicles with significantly longer driving ranges and faster charging times. The approach might also help address concerns about lithium supply chains. By making each battery more durable and efficient, the technology could reduce the total amount of lithium needed.

The same silver-coating technique could potentially be applied to other types of solid electrolytes beyond LLZO, including sulfur-based materials that might offer additional chemical stability. Researchers are also exploring whether the approach could work with sodium-based batteries, which are cheaper and more abundant than lithium-based alternatives but face similar cracking problems.

The simplicity of the solution—applying a tiny amount of silver and heating it—suggests the technique could be relatively straightforward to implement in manufacturing. This practical advantage sets it apart from more complex approaches that might be difficult or expensive to scale up to industrial production levels.

The research team is currently investigating how applying mechanical pressure from different angles might further extend battery lifespan. They are also studying whether the silver coating remains effective when combined with other battery components in complete cells.

While significant questions remain about scaling and long-term performance, the Stanford findings represent a meaningful step forward for solid-state battery technology. The discovery that a nanoscale silver treatment can dramatically strengthen ceramic electrolytes opens a new path toward batteries that could transform energy storage for electric vehicles and countless other applications.